Modular XYZ Xpansion ™ Pins

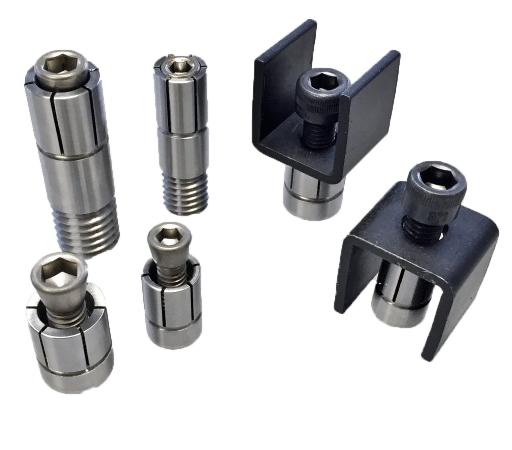

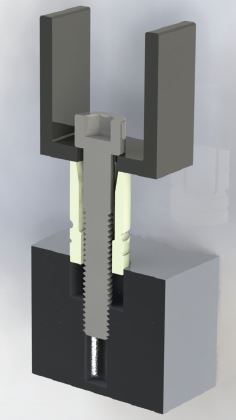

Mitee-Bite Products has launched its new Modular XYZ Xpansion™ Pins for tombstone, grid plate, and fixture plate applications.

This patent-pending special design provides high precision, repeatability, and strong holding force for securing internally bored parts.

Advantages of XYZ Xpansion Pins

● Easy positioning without the need for external clamping elements

● Labor savings and high accessibility on all working surfaces

● Ability to grip internal diameters without drilling or external pressure

Pin Types and Sizes

Threaded Pins

Suitable for tombstone, grid plates, and fixture applications.

Standard sizes: 1/2, 5/8, M12, M16

Press Fit Pins

Preferred for special applications.

Standard sizes: 1/4, 3/8, 1/2, 5/8, M6, M10, M12, M16

Both pin series are made from heat-treated 17-4PH stainless steel.

Press Fit models also have a 12L14 mild steel option.

Technical Specifications

● Expansion tolerance up to 0.030” (7 mm)

● Machinable structure at specific diameters

● Secure contact during loading/unloading thanks to the tapered top form

● Ideal for secondary operations, setup stations, and quick setups within workshops

XYZ Xpansion Pins are designed not only for CNC machines but also for water jets, wire EDM, manual fixtures, or custom machining centers.

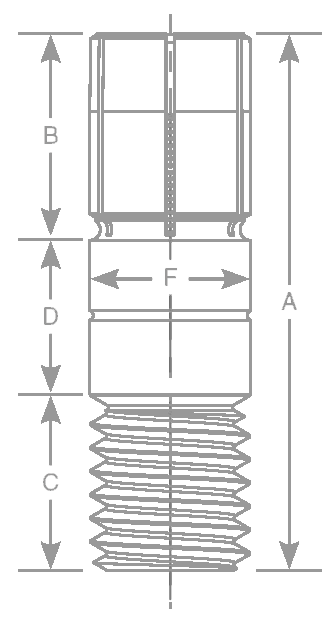

Threaded Pins

Threaded XYZ Pins (in 17-4PH) include an internal hex socket for simple installation and removal from a tombstone, grid plate, or fixture plate. Threaded Pins can be mounted into a drilled and reamed hole for precise positioning or placed into a hardened drill bushing for additional strength and wear resistance. To install a threaded XYZ Pin into a precision hole, drill/ream accordingly and the hole’s nominal diameter should be +0.0001 to +0.0005″ (+0.003 to +0.013mm).

Threaded Pins

* G – minimum diameter pin can be machined or turned down |

Available in every size

Available in every size

both 17-4PH and 12L14

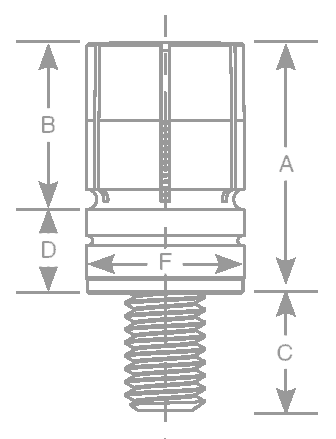

Press Fit Pins

Pins are designed for press fit or close tolerance removable slip fit applications. Install into a precision hole or bushing with center thread for taper screw. If precise positioning is not required, pin can be used on top of fixture plate. An accessory kit is available to make Installation and Removal (I/R) of XYZ Pins quick and easy.

Note: If inserting pin into fixture beyond the slots, ensure clearance is provided for expanding sections.

17-4PH Part No. | 12L14 Part No. | Description | A | B | C | D | E | F (+/-) .000/.001″ (.000/.025mm) | G* | Repl. Taper Screw | Installation/ Removal (I/R) Tool Kit** | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

31730 | 31630 | Press Fit 1/4″ | 0.500″ | 0.27″ | 0.29″ | 0.23″ | 5-40 | 0.250″ | 0.219″ | 31731S | 31720 | |

38730 | 38630 | Press Fit 6mm | 13mm | 7mm | 7.3mm | 5.8mm | M3x.5 | 6.00mm | 5.5mm | 38731S | 38720 | |

31740 | 31640 | Press Fit 3/8″ | 0.750″ | 0.50″ | 0.33″ | 0.25″ | 8-32 | 0.375″ | 0.281″ | 31002S | 31721 | |

38740 | 38640 | Press Fit 10mm | 19mm | 12.7mm | 8.4mm | 6.35mm | M4x.7 | 10.00mm | 7.5mm | 38002S | 38721 | |

31750 | 31650 | Press Fit 1/2″ | 0.750″ | 0.50″ | 0.45″ | 0.25″ | 1 / 4-20 | 0.500″ | 0.413″ | 31010S | 31722 | |

38750 | 38650 | Press Fit 12mm | 19mm | 12.7mm | 11.1mm | 6.35mm | M6x1.0 | 12.00mm | 10.5mm | 38010S | 38722 | |

31760 | 31660 | Press Fit 5/8″ | 0.750″ | 0.50″ | 0.52″ | 0.25″ | 5 / 16-18 | 0.625″ | 0.472″ | 31020S | 31723 | |

38760 | 38660 | Press Fit 16mm | 19mm | 12.7mm | 13mm | 6.35mm | M8x1.25 | 16.00mm | 12mm | 38020S | 38723 |

* G – Minimum diameter pin can be machined or

** turned down up to. Includes set screws (2) SHCS Pin

tapered screw included

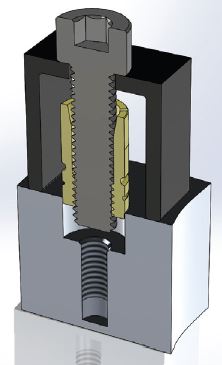

Press Fit Installation

Insert the pin into the prepared hole, place the I/R Tool on the pin as shown.

Using the provided small socket head cap screw (SHCS),

pull the pin evenly into the fixture. When ready to use,

remove the SHCS and replace it with the tapered screw.

Press Fit Removal

Place the I/R tool over the clamp as shown. Insert the larger SHCS into the

“internal threads” of the Pin

and tighten the screw to remove the Pin.

Note:

When the pin needs to be removed frequently, it is recommended to fit the Pin with a drill bushing. Alternatively, drill the hole diameter to the minimum nominal diameter between +0.0001 to +0.0005″ (+0.003 to +0.013mm) and ream.